Understand how aluminum extrusion window frames offer a durable and sustainable option for modern construction.

Key takeaways:

- Aluminum extrusion creates precise and consistent window frame profiles.

- Benefits of aluminum extrusion include complex designs, strength-to-weight ratio, durability, maintenance ease, and sustainability.

- Aluminum extrusion outperforms wood and PVC in terms of sustainability.

- Notable buildings using aluminum extrusion window frames include the Empire State Building, Innovation and Design Building in Boston, and the Edge in Amsterdam.

- Aluminum window frames offer advantages in resistance to UV radiation and corrosion.

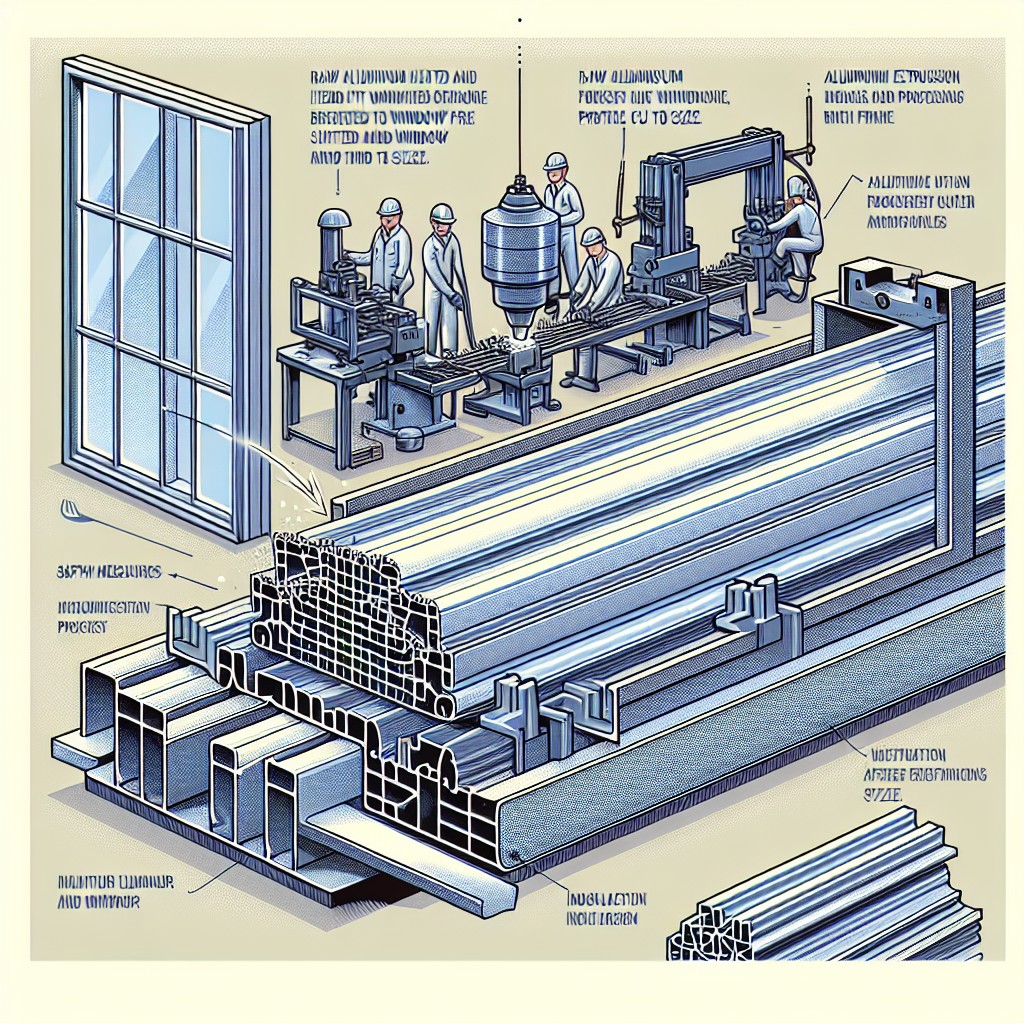

The Process of Aluminum Extrusion

Aluminum extrusion transforms aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses. Here’s a digestible rundown:

– **Heating the Billet**: A cylindrical block of aluminum, known as a billet, is preheated to make it malleable. – **Extrusion Press**: The heated billet is then transferred to an extrusion press, where it’s forced through a die. – **Creating the Profile**: The die has a specific shape that determines the profile of the extruded section, which in this case, matches a window frame design. – **Cooling Process**: Extruded aluminum emerges from the die and is cooled immediately. This helps maintain the newly formed shape. – **Stretching and Cutting**: After cooling, the extruded profiles are stretched to straighten and then cut to the desired length. – **Aging**: Last, a heat treatment or aging process hardens the aluminum to enhance its strength and durability.This sequence delivers precise and consistent window frame profiles to meet the specific needs of architecture and design.

Advantages of Aluminum Extrusion in Window Frame Production

Aluminum extrusion offers several compelling benefits in manufacturing window frames. First and foremost, the process enables complex cross-sectional profiles, accommodating intricate designs for improved aesthetics and functionality. This adaptability translates into better sealing and insulation capabilities, contributing to energy efficiency in buildings.

In addition, extruded aluminum frames are renowned for their strength-to-weight ratio, which supports large glass panes without cumbersome reinforcement, allowing for more light and expansive views.

Durability is another significant advantage. Unlike wood, which may warp or rot, or vinyl, which can become brittle over time, extruded aluminum frames resist the elements with uncanny longevity. They are impervious to pests and fire-resistant, enhancing their appeal for both residential and commercial applications.

Furthermore, these frames offer maintenance ease. A simple wipe down is usually enough to keep them looking new, unlike other materials that may require regular painting or staining. Lastly, aluminum can be recycled indefinitely without losing quality, making it a sustainable choice for eco-conscious consumers and builders.

Comparison of Aluminum Extrusion to Other Materials in Terms of Sustainability

Considering sustainability, aluminum extrusion window frames offer distinct advantages over traditional materials like wood or PVC. Aluminum is inherently corrosion-resistant, diminishing the need for frequent replacements or maintenance—a nod toward long-term environmental impact and resource conservation.

Moreover, the material’s recyclability stands out. Aluminum can be recycled indefinitely with only a fraction of the original energy input required to process raw aluminum, thereby reducing the carbon footprint. In contrast, materials like PVC are not as easily recyclable and can release harmful chemicals if not disposed of properly.

Wooden frames, while biodegradable and renewable, often involve deforestation and a more significant energy consumption in processing. They also require regular treatment with chemicals to resist the elements, which may raise environmental concerns.

Energy efficiency is another sustainability feature. Aluminum frames can be designed with thermal breaks that reduce heat loss, promoting energy conservation in buildings. This aspect underscores a structure’s overall eco-friendliness by minimizing heating and cooling needs.

Each of these points contributes to a holistic understanding of why aluminum extrusion offers a sustainable option, taking both the end-of-life cycle and energy usage into account.

Case Studies of Buildings Utilizing Aluminum Extrusion Window Frames

Several high-profile structures demonstrate the benefits and versatility of aluminum extrusion window frames. The Empire State Building, an iconic landmark, underwent a window retrofit that involved replacing 6,514 double-hung windows with aluminum extruded frames. This change contributed to a significant increase in energy efficiency, reducing the building’s energy costs by around $410,000 annually.

The Innovation and Design Building in Boston showcases the application of aluminum extrusion frames in a retrofit of a historic structure. The upgrade to thermally improved aluminum frames enhanced the aesthetic appeal while improving insulation, demonstrating that modern advancements can coexist with classic architecture.

In a new construction example, the Edge in Amsterdam, touted as one of the world’s greenest buildings, incorporates an intelligent aluminum window frame design. By using extruded frames with integrated automation systems for shading and ventilation, the building optimizes natural light and energy usage, aligning with its sustainable design philosophy. The result is a cutting-edge workspace that pushes the boundaries of what aluminum extrusion window frames can achieve in modern architecture.

FAQ

Are window frames extruded aluminum?

Yes, window frames can be made from extruded aluminum.

What are the disadvantages of aluminum window frames?

Aluminum window frames are often pricier than uPVC counterparts and can suffer from condensation and corrosion issues over time.

Can aluminium be used for window frames?

Yes, aluminum can be used for window frames, offering robust durability and minimal temperature-induced deformation.

Why is it better to make window frames out of aluminium and not steel?

Aluminum window frames offer superior resistance to UV radiation and weather-induced corrosion compared to steel, ensuring long-lasting color and structural integrity without rusting.

How does the thermal performance of aluminum frames compare to other window frame materials?

Aluminum window frames generally have lower thermal performance compared to wood or vinyl frames due to their higher thermal conductivity.

What innovations in aluminum extrusion technologies are enhancing the functionality of modern window frames?

Recent innovations in aluminum extrusion technology for modern window frames include thermal breaks for improved insulation, more intricate profile designs for enhanced structural integrity, and advanced anodizing and powder-coating processes for better durability and color retention.

Can aluminum window frames be designed to meet passive house standards for energy efficiency?

Aluminum window frames can be designed to meet Passive House standards for energy efficiency by incorporating thermal breaks and high-performance glazing.

Recap