This article examines the benefits and considerations of aluminum extrusions for house windows, ensuring you make an informed decision for your home.

Key takeaways:

- Aluminum extrusions offer durable, lightweight, and versatile window frames.

- The extrusion process allows for complex designs and integration of special features.

- Aluminum window frames have superior strength-to-weight ratio compared to wood, vinyl, and fiberglass.

- Thermal breaks in aluminum frames enhance energy efficiency and insulation.

- Aluminum extrusions are evolving to meet the demand for sustainable building practices.

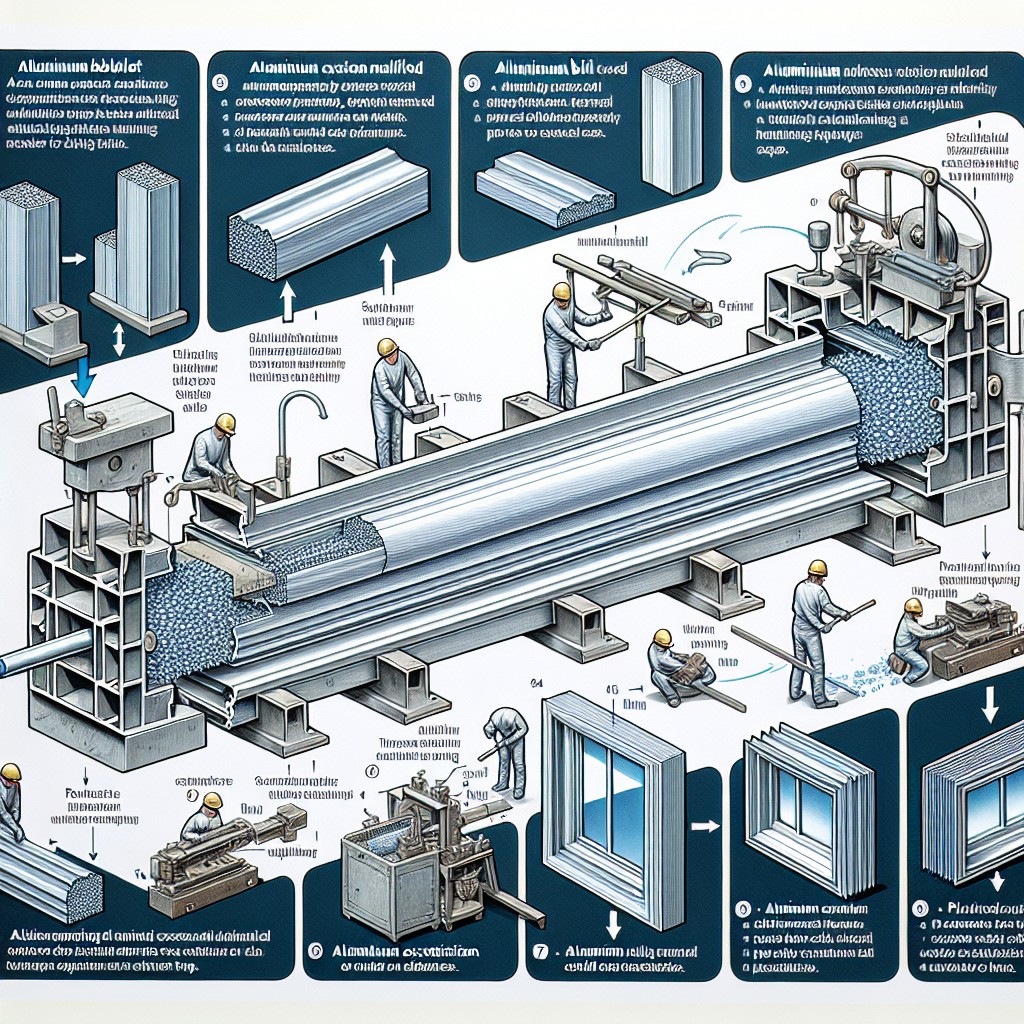

The Process of Aluminum Extrusion for Window Frames

Aluminum extrusion transforms aluminum alloy into definitive cross-sectional profiles for a wide range of uses, including window frames. The technique involves preheating the aluminum to a specific temperature to make it malleable. It’s then forced through a die, which is essentially a mold designed to create the desired shape. As it cools, it maintains this profile, which is then cut to length and may undergo further processes such as anodizing or painting to increase its corrosion resistance and aesthetic appeal.

The extruded aluminum offers precision in the design of window frames, allowing for complex cross-sections that can accommodate the window hardware, thermal breaks, and glazing systems effectively. Since the extrusion process is highly adaptable, special features like channels for weather stripping or grooves for window sashes can be integrated directly into the profile, aiding in the construction of more advanced window systems.

The adaptability of this process leads to efficient and high-speed production of uniform window frames. Aluminum’s strength-to-weight ratio also means that frames are durable yet lightweight, simplifying installation and handling. The end product is a frame that provides structural integrity, design flexibility, and contributes to the overall performance of the window.

Comparison of Aluminum Window Extrusions to Other Materials

When it comes to choosing window frame materials, aluminum stands out for its strength-to-weight ratio which is superior to wood and vinyl. Unlike wood, which can warp, rot, or require regular painting, aluminum frames are virtually maintenance-free, resisting the elements with ease. In contrast to vinyl, aluminum offers a more robust profile that can hold larger panes of glass, crucial for modern, expansive window designs.

Furthermore, aluminum extrusions provide a sleek, contemporary look that is hard to achieve with fiberglass or composite materials. These alternatives may offer insulation benefits, but they lack the malleability that allows aluminum to be fabricated into various complex shapes and thin frames – a clear advantage for architects aiming for a minimalist aesthetic.

While steel is another strong competitor, it is heavier and usually more expensive than aluminum. Steel frames also typically demand more energy in fabrication, tilting the scales in favor of aluminum’s lower overall environmental impact. Noteworthy too is that aluminum’s thermal performance has vastly improved with the advent of thermal breaks, significantly narrowing the insulating advantage once held by materials like wood and vinyl.

Advantages of Aluminum Window Extrusions for Energy Efficiency

Aluminum’s inherent strength allows for thinner frames and larger glass panels, enhancing natural light and reducing the need for artificial lighting. Thermal breaks, a feature in these extrusions, can be integrated to minimize heat transfer, creating a barrier between the inside and outside aluminum surfaces.

Pairing aluminum frames with energy-efficient glass options significantly enhances their performance, leading to potential savings on energy bills and more stable indoor temperatures. Additionally, the material doesn’t warp or swell under temperature changes, maintaining a snug fit for windows over time, which is crucial for preventing air infiltration.

These energy-conservation qualities place aluminum window extrusions high on the list for those seeking to bolster their building’s green credentials.

The Future of Aluminum Extrusions in Sustainable Building Practices

With increasing emphasis on green construction, aluminum extrusions are evolving to meet the demand for more energy-efficient and eco-friendly homes.

Innovation in alloys: Researchers are developing new aluminum alloys with enhanced properties such as improved thermal insulation and structural strength, which are key for sustainable construction.

Thermal breaks: Advancements in extrusion technology have led to the widespread use of thermal breaks within aluminum frames, reducing heat transfer and enhancing energy efficiency.

Recyclability: Aluminum’s inherent recyclability makes it a material of choice for sustainable building, as it can be melted down and reused with minimal quality loss, reducing the ecological footprint.

Integration with renewable energy systems: The adaptability of aluminum extrusions enables seamless integration with solar panels and other renewable energy systems, making it an instrumental material in the design of energy-producing windows.

Coating technologies: The development of advanced coatings that reflect infrared light helps aluminum-framed windows to keep interiors cooler in summer and warmer in winter, contributing to reduced HVAC loads.

These points highlight aluminum’s integral role in the future of eco-conscious architecture, as the industry strives to combine performance with environmental stewardship.

Recap